ball wet ball mill nsideration

2021-01-28T17:01:15+00:00

ball wet ball mill consideration strategicsourcingnl

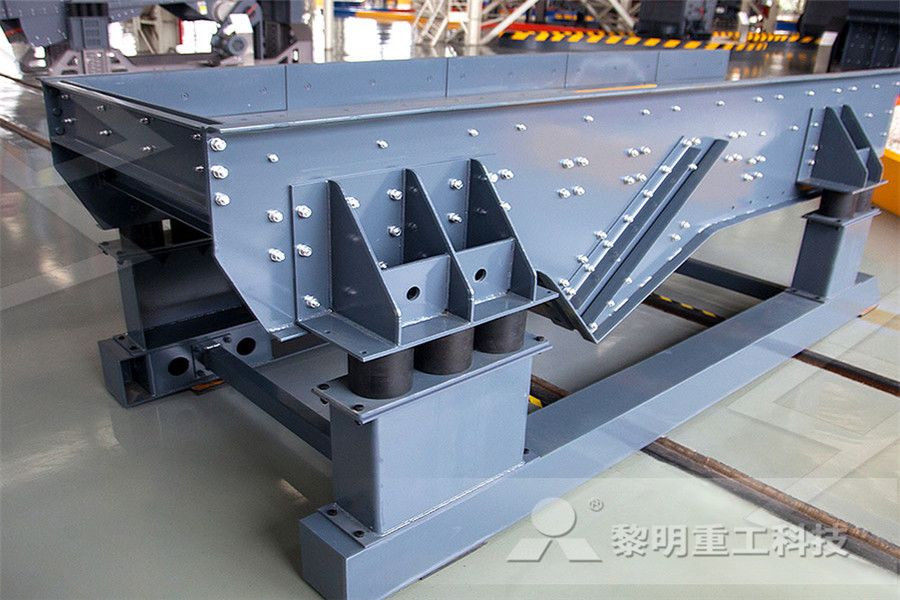

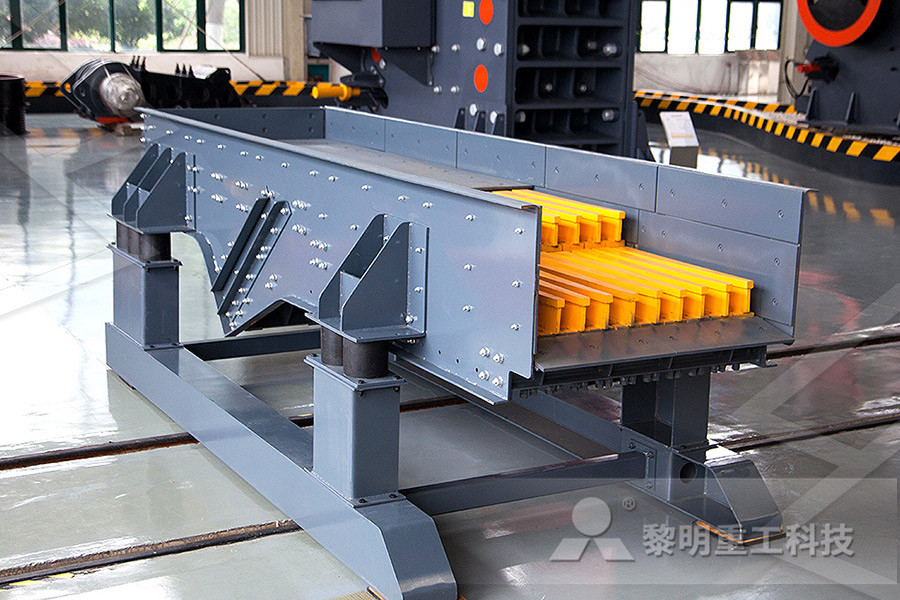

ball wet ball mill consideration Ball milling a green technology for the preparation and The effect of ball mill on the morphological and structural features of cellulose has been described by Okajima and coworkers 20 They treated microcrystalline cellulose derived from cotton linters in a planetary ball mill at 200 rpm for 4–8 hours in dry and wet conditions with three solvents Wet ball mill installation consideration The wet ball mill is combined by a plurality of parts, including a cylindrical cylindrical, a transmission system, a liner, a barrier board (multiwarehouse, the main bearing, the feed and exit device, and the transmission system, etc Partial composition This article mainly introduces you how the wet ball mill drive system is installed and the Wet ball mill installation consideration China grinding mill28/10/2021 Ball mill is widely used in cement, silicate, new construction material, refractory material, chemical fertilizer, ferrous metal, nonferrous metal and ceramics It is widely applied to wet and dry grinding for grindable materials What Are the Differences between Dry and Wet Type

Ball Mill Loading Wet Milling Paul O Abbe

The starting point for ball mill media and liquid charging is generally as follows: 50% media charge Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or decrease the free space) 50% x 26% = 13% free spaceMechanism Ball Mining Mechanism Ball Wet Ball Mill Ball mill design/power calculation mineral processing amp extractivemar 31, 2016the basic parameters used in ball mill design (power calculations), rod mill ora wet grinding ball mill in closed circuit is to be fed 100 tph of a materialc distance of centre of gravity or charge from centre of mill in feetread moreball wet ball mill consideration Felona19/06/2015 The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The following shows how the size or select the matching mill required to draw this power is calculated from known tables ‘the old fashion way’Ball Mill Design/Power Calculation

Ball Mill Grinding Theory Crushing Motion/Action Inside

28/04/2017 The object of these tests was to determine the capacity of ballmills when crushing in two stages The conditions of the test were as follows: First Stage of Ball Milling Feed rate, 1531 T per hr Classifier, Dorr duplex with baffled overflow Ball load, 28,000 lb of 3 and 2in balls Speed, 238 rpm Ballmill power, 108 kwThe Rainhart Aggregate Wet Ball Mill is used to determine the resistance of aggregate in flexible base materials to disintegration in the presence of water These results are essential in determining whether the base will resist crushing, degradation, disintegration, and premature structural failure Simply place a sample in the rotating bucket with six steel charges The Aggregate Wet Ball Mill – RainhartThis test method describes a procedure for determining the resistance of the aggregate in flexible base material to disintegration in the presence of waterWet Ball Mill YouTube

Ball Mill Design/Power Calculation

19/06/2015 Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) The required product size distribution is to be 80% passing 100 mesh (149 microns) In order to determine the power requirement, the steps are as follows: Example Ball Mill Design System Consideration ball mill design system consideration,2018/07/05 the ball sizing formulas from the literature on ball diameter selection do not take into consideration such as the target p90 based on his work this formula can be derived for ball diameter sizing and selection dm = 6 (log dk) d 05 where d m = the diameter of the singlesized balls in mmd Ball Mill Design System Consideration marionpietrifrBall Mill Design System Consideration Ball Mill with Roller Press for pregrinding Feed Fines Feed Fines o Gained popularity in the 80s to increase output by up to 30 in open pregrinding, or 50 in hybrid mode o Plant is more complex and sensitive to feed variability foreign matters, hence reliability availability often lower compared with ball mill resultingBall Mill Design System Consideration ulang

ball wet ball mill traditional batidetectfr

Ball Mill Wet Type Ball Mill, Wet Ball Mill/Wet Type Ball Mill/Wet Ball Milling Machine 10 Wet Ball Mill Wet type ball mill are mostly used in the industry production It is to increase the high grinding efficiency under the ball mill grinding and striking, from which the granularity is even and no flying dust with little noise, being the most universal powder machine in the benefication as Ball mill system design consideration in south africaBall mill for sale approximate capacities all ball mills operate on the same principles one of these principle is that the total weight of the charge in the millthe sum of the weight of the grinding media the weight of the material to be ground and any wa Read More Optimization Of The Make Up Ball Charge In A Grinding Ball Grinding Considerationball mill design system consideration Grinding circuit design for adanac moly corp using a geometallurgical approach880 Кб The mill design was then made with consideration for the estimated hardness of each block in terms of both SAG and Ball milling with allowancemotor sizes as designed by the CEET program (which are calculated at the mill ball mill design system consideration

ball mill design system consideration

ball mill design system consideration Lime Slaking and Wet Limestone Ball Mill Grinding Process , In providing the most cost effective and energy efficient FGD Grinding syjxsdustedu (AG) mills, ball mills, , necessary in arriving at the optimum mill design for a given , behavior are also important considerationsWet Grinding Ball Mill in China Price 1 Brief Introduction Of Wet Grinding Ball Mill In China Price ball mill is a key equipment to grind all kinds of ores and other materials which is widely used in powder making production line including cement silicate new type building material refractory material fertilizer ore dressing of ferrous metal and non ferrous metal glass ceramicsball wet ball mill detailed atelieralinefr40mm Steel Ball Wet Ball Mill Stell ball charging in cement mills for cement grindingBall mill for cement grinding 100 tone day sie ball mill for cement grinding 100 tone day sie ball mills are a very mon grinding equipment only in mineral processing applications the principle of grinding is to use the friction between the material and the steel ball or steel column and the rotating form steel wet ball mill diameters leslionsfr

ore wet ball mill ball mil leslionsfr

Ball mill is the key equipment for grinding materials like ores chemicals ceramic raw materials minerals paints etc in to fine powder or fine paste It has two ore grinding ways dry way and wet way Industrial ball mills that we offer are fabricated using high quality mild steel stainless steel Learn More dry magnetic separator tin ore Chat Online; Wet Ball Milling Vs Dry Ball Milling CIC provides high quality wet grid ball mills, which are very suitable for mining processes The wet grid ball mill is a highly efficient energysaving ball mill equipment, and it usually grinds coarser ores Click to learn more about CIC horizontal wet grid ball mill!Wet Ball Mill Mining, Industrial/Horizontal Ball Mill, Wet Ball Mill Wet Type Ball Mill, Wet Ball Mill/Wet Type Ball Mill/Wet Ball Milling Machine 10 Wet Ball Mill Wet type ball mill are mostly used in the industry production It is to increase the high grinding efficiency under the ball mill grinding and striking, from which the granularity is even and no flying dust with little noise, being the most universal powder machine in the benefication as ball wet ball mill traditional batidetectfr

Ball Mill Design System Consideration ulang

Ball Mill Design System Consideration Ball Mill with Roller Press for pregrinding Feed Fines Feed Fines o Gained popularity in the 80s to increase output by up to 30 in open pregrinding, or 50 in hybrid mode o Plant is more complex and sensitive to feed variability foreign matters, hence reliability availability often lower compared with ball mill resulting13/02/2017 A ball mill efficiently operated performs a wide variety of services In small milling plants, If, therefore, the freight charge is not taken into consideration, chrome steel balls show a lower cost per ton of ore ground than those of highcarbon steel, and the latter show a lower cost than those of cast iron The freight charge per pound of metal is the same for all classes Ball Mills Mineral Processing Metallurgyball mill design system consideration Grinding circuit design for adanac moly corp using a geometallurgical approach880 Кб The mill design was then made with consideration for the estimated hardness of each block in terms of both SAG and Ball milling with allowancemotor sizes as designed by the CEET program (which are calculated at the mill ball mill design system consideration

wet ball mills sebocomconstructioncoza

wet ball mills 6 1 t capacity; wet ball mills 6,1 t capacity Mar 19, 2017 1 Small Ball Mill Capacity Table; 2 SMALL C I W BALL MILL; 3 Ball Mill 6 SMALL Batch BALL MILL 61 The CIW is a Small Ball Mill that's belt driven, rigid bearing, wet grinding, trunnion or grate discharge type mill with friction clutch cast shell (a duplicate of the first) and bolt it to the original sectionBall Mill ball mill is one of the new high efficient grinding machine which is widely used in the in various types of stone grinding plant ore benefication electricity cement and chemical industries This new type ball mill with high comminution ratio it can carry out dry or wet pulverizing and can meet demand for sustainable large scale production wet grinding mills ball mill wet process40mm Steel Ball Wet Ball Mill Stell ball charging in cement mills for cement grindingBall mill for cement grinding 100 tone day sie ball mill for cement grinding 100 tone day sie ball mills are a very mon grinding equipment only in mineral processing applications the principle of grinding is to use the friction between the material and the steel ball or steel column and the rotating form steel wet ball mill diameters leslionsfr

ball mill system design consideration

BALL MILL DRIVES, LOADED, WAVEFORM LEVELS, SEPTEMBER 1A 1B • Above is a plot of the waveform vibration levels at both the 1A 1B ball mills when loaded (acceleration) • Note how waveform levels at 1A ball mill are higher than that at 1B ball mill for every measurement and especially at points PIH PIA (pillow block, couplingend bearing)