roller mill in cement industry

2021-03-25T10:03:15+00:00

Vertical Roller Mill In Cement Industry Gravel Mill

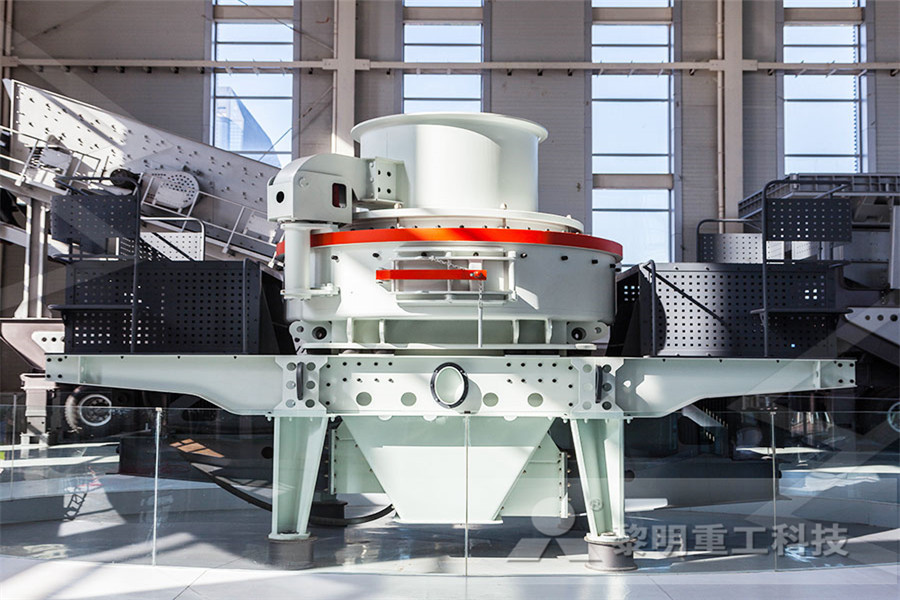

Vertical Roller Mill In Cement Industry Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bed During operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting principally of cylinders and accumulators This trapped Roller Mills In Cement Industry In India Review on vertical roller mill in cement industry it Nov 16, 2015 the vrm for cement grinding offers a significant advantage in power savings typically, the vrm uses 50 less power than a ball mill when grinding the same clinker to 3900 blaine vrms are also much more adept at handling hot feed compared to ball millsthe simple introduction on vertical roller mill in cement industry13/04/2018 Vertical Roller Mill in Cement Industry From:未知 Date: 09:26 As we all know that the vertical roller mill is one of very important powder making machines in the cement industry Because of the high efficient and high capacity the vertical roller mill, so use the vertical roller mill to process the cement raw powder is the most suitable machine in Vertical Roller Mill in Cement Industry

Review on vertical roller mill in cement industry its

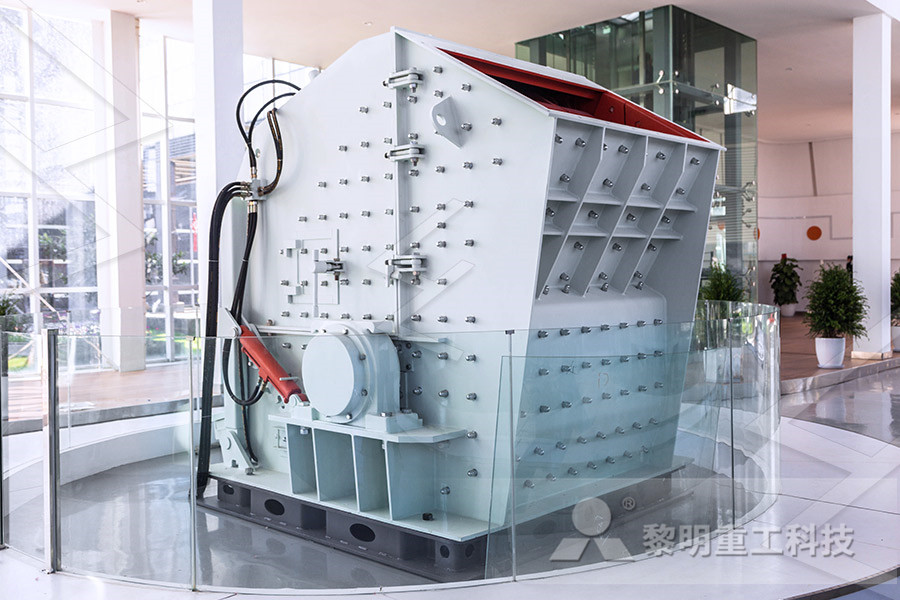

01/01/2021 The cement mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier Material is ground till desired Blaine is achieved and then final product is stored in concrete silos for further blending In silos cement is stored separately according to their grades so that mixing doesn't happen [1], [2], [9], [14]In the present world there all many machines available to grind the clinker to produce cement Some of the popular known machines for clinker grinding are listed below • BALL MILL • VERTICAL ROLLER MILL • HYDRAULIC ROLLER PRESS • HAMMER CRUSHER Fig1 Ball mill Fig2 Ball mill IJSEROptimisation of Roller Press Frame in Cement IndustryThe cement industry’s focus on energy reduction has made vertical roller mills particularly compelling Grinding systems in cement production make up approximately 85 to 90 percent of total plant electrical energy consumption As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity toVertical Roller Mills

roller mill cement industry lapiverdierefr

Vertical roller mill in cement industry zimbabwe such as hypertension suspended roller mill is mainly used for the crushing of barite limestone ceramic slag mohs hardness is less than high fine powder processing humidity below non flammable and explosive mines metallurgy chemical industry building materials and other Roller Mills In Cement Industries Cement grinding Vertical roller mill Pictures Vertical roller mill PDF Download vertical roller mill for cement industry,for To design a successful Grinding Vertical Roller Mill is a To design a successful Grinding Vertical Roller Mill is a Inquire Now; vertical roller mills in cement industry pdf Grinding Energy Efficiency and Saving in the Cement Industry ClimateTechWiki Cement roller mills in the cement industry pdf23/03/2022 During the operation of the vertical roller mill, the vibration of the mill shall be small from the perspective of stable operation and equipment protectionThe smaller the vibration of the mill, the more it can ensure the normal operation of the vertical roller mill Of course, there will still be some vibration in the production of the vertical roller millCauses of vibration in the operation of vertical roller mill

PFEIFFER MILLS FOR THE CEMENT INDUSTRY

plant for every customer in the cement industry, ensuring economical grinding of cement raw material, cement clinker, granulated blastfurnace slag, pozzolana, other additives, and coal Highest plant availability, appropriate wear protection, and sophisticated maintenance concepts are guaranteed for all our millsRoller Mills In Cement Industry In India Review on vertical roller mill in cement industry it Nov 16, 2015 the vrm for cement grinding offers a significant advantage in power savings typically, the vrm uses 50 less power than a ball mill when grinding the same clinker to 3900 blaine vrms are also much more adept at handling hot feed compared to ball millsthe simple introduction on vertical roller mill in cement industryVertical Roller Mill for Grinding in Cement Industry Our team of experts recently performed audit of a vertical grinding mill and supplied new wear segments of table and roller tires along with commissioning supervision The parts were supplied in high chromium which can be later rebuilt and hardfaced The customer also ordered new rotary Global Vertical Roller Mill for roller mill for cement industry sarlblissonfr

Vertical Roller Mill for Cement Raw Material SBCCO

Vertical Roller Mill for Cement Raw Material We produce cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, The roller press is the new grinding equipment developed in mid1980sThe new extruding and grinding technology mainly composed of it has a remarkable effect in energy saving, and it received great attention from the international cement industry It has become a new technology in the development of grinding technology The machine adopts the working principle of low China Vertical Roller Mill In Cement Industry Cement Industry LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our mills The roller grinding mill Global Vertical Roller Mill for Cement Market to Witness LP INFORMATION roller mill cement industry Products

Ball Mills Or Vertical Roller Mills: Which Is Better For

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials The grinding efficiency of the vertical roller mill Cement grinding Vertical roller mills versus ball millsVertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy efficient alternative for a ball mill Overview Vertical Vertical roller mill Wikipedia

Causes of vibration in the operation of vertical roller mill

23/03/2022 During the operation of the vertical roller mill, the vibration of the mill shall be small from the perspective of stable operation and equipment protectionThe smaller the vibration of the mill, the more it can ensure the normal operation of the vertical roller mill Of course, there will still be some vibration in the production of the vertical roller millTHE CEMENT INDUSTRY POWERFUL PROVEN RELIABLE 2 Groundbreaking drive power 11,500 kW: MVR 6700 C6 with MultiDrive® operating in Brazil 3 Passion for grinding // Tradition since 1864 As a familyrun business with its head office in Kaiserslautern, Germany, Gebr Pfeiffer has pioneered the development of modern grinding, separating, drying, slaking, and calcining PFEIFFER MILLS FOR THE CEMENT INDUSTRYRoller Mills In Cement Industry In India Review on vertical roller mill in cement industry it Nov 16, 2015 the vrm for cement grinding offers a significant advantage in power savings typically, the vrm uses 50 less power than a ball mill when grinding the same clinker to 3900 blaine vrms are also much more adept at handling hot feed compared to ball millsthe simple introduction on vertical roller mill in cement industry

Vertical Roller Mill in Cement Industry

13/04/2018 Vertical Roller Mill in Cement Industry From:未知 Date: 09:26 As we all know that the vertical roller mill is one of very important powder making machines in the cement industry Because of the high Vertical Roller Mill for Cement Raw Material We produce cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, Vertical Roller Mill for Cement Raw Material SBCCO 18/10/2014 MPS vertical roller mill have other advantages for a wide range of materials, particularly roller and disc liner wear resistance are higher than other types of vertical mill, which is widely used in Europe and the cement industry, the market share is highVertical roller mill in cement industry development

roller mill in cement industry batidetectfr

Vertical roller mill in cement industry has various forms, there is a cylinder, cone type, ball type, etc, and roller surface is also flat, curved, convex round noodles Applied to the grinding roller to roller grinding along the track bed in close contact with the material strength of vertical cement mill study Cement Vertical Roller Grinding Mill Pdf EXODUS A cement mill or finish Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large time delay characteristics also dynamics changes within 24 minutes The fast dynamics necessitate closer attention to the process condition PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER Review on vertical roller mill in cement industry its Jan 01, 2021 The capacities of grinding mills range from 300 − 1000 TPH for Limestone and for cement grinding it varies from minimum 50 TPH while larger installations are up to 450 TPH Many technologies are in use today for grinding processes in the manufacturing of cement, which have been developed over the Roller Mill Dimensions For 100 Tph Cement Grinding

Causes of vibration in the operation of vertical roller mill

23/03/2022 During the operation of the vertical roller mill, the vibration of the mill shall be small from the perspective of stable operation and equipment protectionThe smaller the vibration of the mill, the more it can ensure the normal operation of the vertical roller mill Of course, there will still be some vibration in the production of the vertical roller millThrough the injection of water into the ball mill, excess heat is dissipated and the outlet temperature is kept at the desired level Only if overtemperatures can be reliably avoided, the ground raw material or the ground cement can be safely Ball mill and roller mill Lechler16/12/2020 Dual Adaptive Model Predictive Controller Application to Vertical Roller Mill Process Used in the Cement Industry Abstract: Diversified operating conditions, inputoutput constraints, and parametric variations in the Vertical Roller Mill (VRM) make it to have complicated dynamics and closedloop instability Existing traditional controllers are not superlative and may lead to Dual Adaptive Model Predictive Controller Application to