process design for gypsum plaster

2020-05-04T02:05:36+00:00

process design for gypsum plaster shecoachingde

Process gypsum plaster, smooth remove price Inside the house, numerous gypsum plaster work can be carried out This building material plays a role, if you want a pleasant indoor climate Gypsum plaster Material and advantages Gypsum plaster is suitable as a binder only for interior plaster, because gypsum absorbs water and thus can soften What Is Gypsum What 09/10/2017 This dry mix is combined with water, soap foam, accelerators, and shredded paper or pulpwood in a pin mixer at the head of a board forming line The slurry is then spread between two paper sheets that serve as a mold The edges of the paper are scored, and sometimes chamfered, to allow precise folding of the paper to form the edges of the boardGypsum Processing for Cement, Plaster and Wallboard 09/10/2021 The production process of gypsum products can be broken down into four stages: exploration, quarrying, processing, panel production The data resulted from the first process, ie, the exploration process is used to determine the configurations of the components used in the later stages of gypsum productionPRODUCTION PROCESS OF GYPSUM enadaktco

Gypsum processing and use Humanitarian Library

from flue gas desulphurisation; a process for cleaning up emissions from chimneys to reduce the quantity of sulphurous gases flowing into the atmosphere Dehydration: Rock into plaster Gypsum rock is converted into gypsum plaster by driving off some of the chemically combined water Heating gypsum at 120°C for one hour results in a hemihydrate (CaSO 41⁄2H 2O) – During the process, the phases of the CaSO 4 x H 2 O system can be optimally adjusted Rotary kilns are used for the calcining natural gypsum In this process, precrushed natural gypsum is calcined in parallel flow with the flue gas Fine grinding mills then grind it to its final particle size FactSheet Rotary kiln (EN)Calcining processes for natural and synthetic gypsum By drying off some of the chemically combined water from the Gypsum rock, it is converted into gypsum plaster First, the gypsum rock is ground and crushed in the mill to start the process After that gypsum is heated up on a flat metal What Is Gypsum What Is Gypsum Plaster Gypsum

Gypsum Plastering Cement Application for Internal

Gypsum plaster is mixed with clean water in recommended proportion at site to make a consistent slurry Gypsum plaster slurry is then applied at desired 16/12/2021 Gypsum plasters can be divided based on the heat energy they get throughout the manufacturing process Below are the two types of gypsum plaster– Plaster made from anhydrite gypsum heated to 1700C; Plaster is made from hemihydrate gypsum, which is made by heating gypsum, formulated with special additives like perlite, vermiculite to enhance What is Gypsum Plaster? Use, Benefits and Types of Plaster is made by heating gypsum (CaSO42H2O) powder, thus converting it to calcium sulphate hemihydrate (CaSO4½H2O) The hemihydrate is also known as stucco or Plaster of Paris Probably so named because of the very large Design And Production Of Ceiling Board Using Plaster Of

How to properly apply Gypsum Plaster on walls?

Gypsum Plaster should be finished to a good degree of smoothness before painting The surface is usually sand papered (not with emery paper) to give it a further smoother finish All horizontal lines and surfaces should be tested with To produce plasters or wallboard, gypsum must be partially dehydrated or calcined to produce calcium sulfate hemihydrate (CaSO4 ½H 2O), commonly called stucco A flow diagram for a typical gypsum process producing both crude and finished gypsum products is shown in Figure 11161 In this process gypsum is crushed, dried, ground, and calcined Not all of the 1116 Gypsum Manufacturing United States Environmental This project deals with the design and production of ceiling board using Plaster of Paris [POP] gypsum materials Plaster of Paris [POP] is a white powdery mixture of gypsum It has been named such because the first deposit of gypsum was found in Paris This powder when mixed with water solidifies, but without losing its volume During manufacturing process, the Design And Production Of Ceiling Board Using Plaster Of

Calcining processes for natural and synthetic gypsum

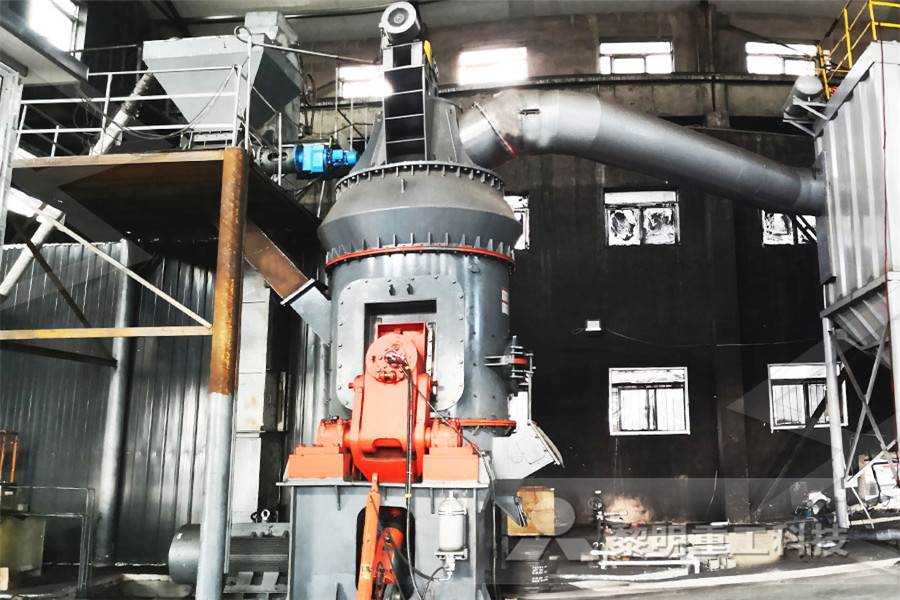

To ensure targeted, highquality processing into gypsum plaster, plasterboard or gypsum blocks, you need technology solutions that process natural or synthetic gypsum into stucco or highfired plaster With its indepth knowhow, Grenzebach finetunes calcination specifically to the nature of the raw material, the properties of the end product, and individual operating Configuration of Bhutanese gypsum plant and production of gypsum plaster by the process suggested by CBRI visàvis to process adopted by the plant have been explained Gypsum at 180°C with 1 h retention time gave plaster of better setting and strength properties acceptable to market complying relevant standards epcon water technologies private limited d refuse and Plant Design For Plaster Of Paris Manufacturing Process Manufacturing process for gypsum plaster: For walls with surface quality Surfaces give rooms their homey charm! Gypsum plaster enhances this good feeling and gives surfaces their final touch: a quality standard that becomes your essential benchmark – and therefore ours Contact Gypsum Solution partner in implementing your perfect gypsum plaster formulation Gypsum Gypsum: Production solutions for gypsum plaster Grenzebach

How to properly apply Gypsum Plaster on walls?

Gypsum Plasters can be applied directly to brick walls, concrete blocks, or RCC surfaces Gypsum Plasters usually come in ready mix bags Extract the powder in a dry vessel and mix it with water The mixture has to be stirred for 23 In addition, gypsum is found in volcanic areas and in veins of metallic ores Gypsum plaster is made by heating gypsum at low temperatures to drive off water, to produce plaster of Paris a chalky, fastsetting material commonly What Is Gypsum Plaster 15 Advantage of Gypsum Cement gypsum Schenck Process And gypsum plays a similarly important role inside buildings Be it in the form of gypsum plaster, gypsum plasterboard or wall panels, as a lightweight material with an easytosmooth surface offering good resistance to fire, it's hard to imagine a world without gypsum Benefit from our wide range of cement process design gypsum vukanimaafricacoza

Plaster: Types, Plastering Process, Advantages Disadvantages

It is used in places where the temperature is too high or higher than 50 ° C to remain on the gypsum plasters wall 8Waterproof Plaster: Plastering process: Plaster provides a decorative function where required; it is manufactured from three coats with a thickness of 25 mm The first coat 10 mm thick, is called a scratch coat, the second coat is 10 mm thick known as process design gypsum hoveniersbedrijfvdelzennl New gypsum ceiling design for living room 2019 To finish the gypsum ceiling design, you need a stable stepladder, meter ruler, construction level, screwdriver, punch (if the plates will be attached to the concrete floor), a hammer, a hacksaw or scissors for metal To process GKL you need a drill with special round process design gypsum jakkalsvalleicoza09/10/2021 The production process of gypsum products can be broken down into four stages: exploration, quarrying, processing, panel production The data resulted from the first process, ie, the exploration process is used to determine the configurations of the components used in the later stages of gypsum productionPRODUCTION PROCESS OF GYPSUM enadaktco

Gypsum Plaster: Its Properties, Advantages

30/07/2019 The application of gypsum plaster is a timesaving process, hence cost of the project is reduced Quantum of wastage during application is negligible It is easily workable for an excellent finish Gypsum plaster does All types of gypsum plasters design and development of production formula optimzed as per your local conditions Gypsum plasters production units and equipment Crushing and Screening Unit Gypsum, mined from nature, is Gypsum plasters production plants and equipmentendtoend process solutions for gypsum producers worldwide 2 Claudius Peters EM 59 Mill Operation of Claudius Peters EM Mill Robust design and the highest standards of quality ensure the longest possible service life for Claudius Peters products, even under the most difficult of operating conditions Within its main applications of grinding, drying, grinding calcination or Claudius Peters Gypsum Brochure

Phosphogypsum purification for plaster production: A

PG is used to produce plaster The process optimization was conducted using a full factorial design The significant factors considered in the experimental study are temperature (X1), volume of sulfuric acid solution (X2) and PG quantity (X3) The main effects and interaction effects of these factors on the responses of the % P2O5, % F, Total Organic Carbon (TOC) (mgkg1) Plant Design For Plaster Of Paris Manufacturing Process manufacturing process of gypsum cornice plaster cornices mouldings gypsum cornice 1 more than 1000 designs plaster of paris production line the 7Convenient process 8Light weight TP Thaiplaster Co, Ltd TP Thaiplaster is committed to manufacturing and marketing only best quality gypsum plaster Plant Design For Plaster Of Paris Manufacturing ProcessThe plaster produced with purified PG was found to have similar properties to that produced from natural gypsum Flow diagram for phosphogypsum purification process Major Element Contents of the (PDF) Phosphogypsum purification for plaster

Modern Gypsum Ceiling Designs HPD TEAM

20/03/2020 Gypsum Design; Modern Gypsum Ceiling Designs Top 30 Modern Gypsum Ceiling Designs Choosing the most suitable ceiling design for your living room can be challenging Here are 30 best modern gypsum manufacturing process flow for plaster of paris plaster of paris production plant YouTube flow sheet diagram for the manufacture of gypsum ceiling Gypsum Mining, Production, Processing and Marketing, Planning Gypsum, Gypsum Plaster, and Plaster of Paris at Daud Khel, 30 miles away from milling plaster process flow chart get pricePlant Design For Plaster Of Paris Manufacturing ProcessLooking for Best Gypsum False Ceiling Design for Hall – and want to download So we have shared the best collection of HD Best Gypsum False Ceiling Design for Hall So guys scroll down and enjoy Outstanding Low Height and Floor Bed Design IdeasBest Gypsum False Ceiling Design For Hall 2022