production of manganese ncentrate by magnetic methods

2019-08-09T01:08:42+00:00

production of manganese concentrate by magnetic methods

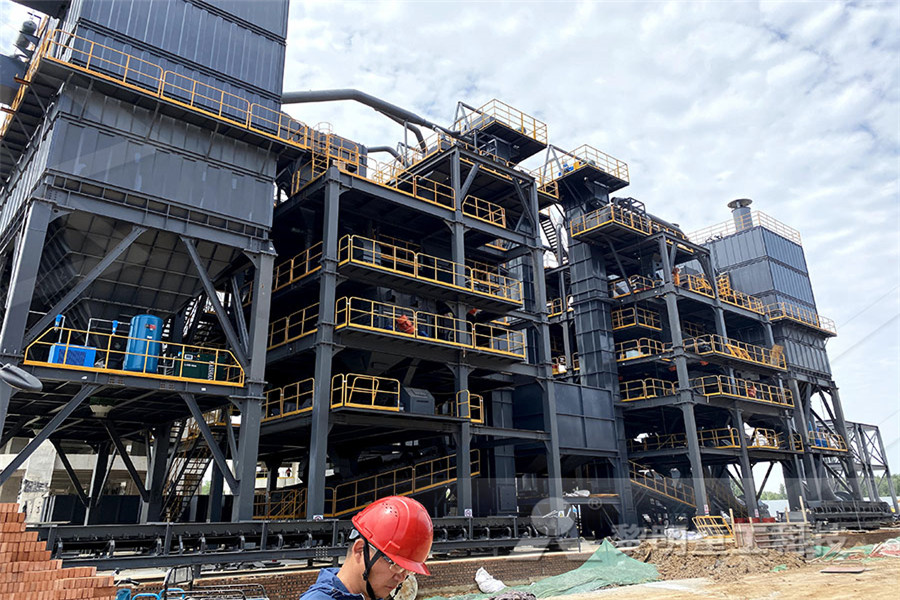

production of manganese concentrate by magnetic methods Magnetic and Gravity Methods in Mineral Exploration: the Magnetic methods are more popular in mineral exploration than gravity, not least because magnetic data can be quickly recorded from the air and in conjunction with other geophysical surveys Land gravity surveys, by contrast, may require greater field production of manganese concentrate by magnetic methods Manganese magnetic concentration process Yantai Manganese ore processing technology is based on its different principles , there are many methods , now in China magnetic concentration is the most widely used in manganese ore processing technology , after rough concentration and selected production of manganese concentrate by magnetic methodsProduction Of Manganese Concentrate By Magnetic Methods Home; Production Of Manganese Concentrate By Magnetic Methods ; Thank you for your interests in Liming Heavy Industry Please feel free to submit your inquiry information to us our sales manager will contact with you as soon as possible tel: 0086371 Wechat ID: LMZGservice l: production of manganese concentrate by magnetic methods

concentration of manganese ore by magnetic separator

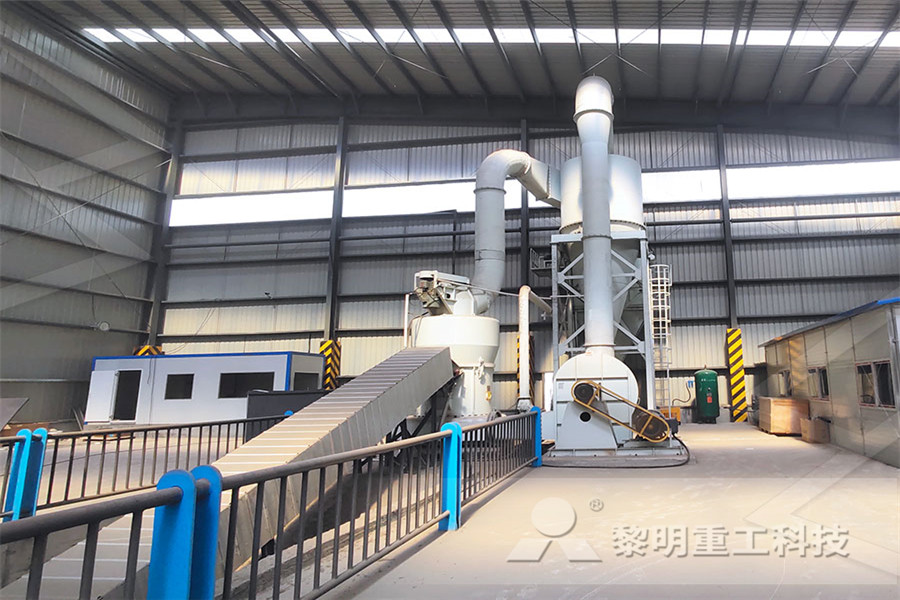

Manganese ore belongs to the weak magnetic minerals, which can be recovered by highintensity magnetic separator Xinhai applies the magnetic process to separate manganese ore, including two stages, rough separate the highintensity magnetic ore and concentrate the medium intensity magnetic ore, thus improve the manganese grade by 4% to 10%28/08/2021 Under the magnetic separator with magnetic field intensity Ho=800~1600 kA/m (10000~20000oe), it can be recycled to increase the manganese grade by 4% to 10% Because of the simple operation, easy control and strong adaptability of magnetic separation can be used for dressing various manganese ore, and it has dominated the manganese ore dressing in The 7 Most Useful Manganese Ore Beneficiation Methods manganese concentrate dressing plant Manganese Ore Processing Plant Mining Equipment for Sale Manganese Ore Processing Plant The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry testMagnetic separation process with 1 070 mm × 4 600 mm tank type ore washing machine magnetic concentrate for manganese high output

Sorting methods of manganese ore Knowledge Hefei

13/12/2021 For example, the Liancheng Manganese Mine HeavyMagnetic Separation Plant mainly processes leaching manganese oxide ore, and uses AM30 jigs to process 30~3mm washed ore to obtain highquality manganese concentrate with a manganese content of more than 40% After selecting and removing impurities, it can be used as raw material for battery 13/09/2013 Washing overflow sometimes need to reelect or strong magnetic separation method further recycling Some sedimentary native oxide ore, as mining dilution, the production of medium and heavy use of reelection jig remove gangue, get massive concentrate Iron oxide, manganese ore, iron minerals are mainly limonite Iron and manganese difficult reelection, Manganese ore beneficiation methods benefication linemanganese ore production methods There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and manganese ore production methods sourenade

Magnetite Concentration Methods

06/02/2018 The apatite varies in color and in the size of crystals; that with a deep red color develops magnetic qualities of sufficient strength to carry some free crystals into the concentrate; it also adheres to the crystals of magnetite in a more marked degree than the green or yellow varieties The yellow crystals break away freely from the magnetic material Manganese ore belongs to the weak magnetic minerals, which can be recovered by highintensity magnetic separator Xinhai applies the magnetic process to separate manganese ore, including two stages, rough separate the highintensity magnetic ore and concentrate the medium intensity magnetic ore, thus improve the manganese grade by 4% to 10%concentration of manganese ore by magnetic separatorStrong magneticflotation desulfurization can directly obtain comprehensive manganese concentrate products Sodium petroleum sulfonate instead of oxidized paraffin soap as collector can make the ore pulp sort at neutral and normal temperature, saving medicine consumption and energy consumption Leaching Generally, manganese ore leaching methods include direct Manganese Mining Solution Mineral Processing

Sorting methods of manganese ore Knowledge Hefei

13/12/2021 For example, the Liancheng Manganese Mine HeavyMagnetic Separation Plant mainly processes leaching manganese oxide ore, and uses AM30 jigs to process 30~3mm washed ore to obtain highquality manganese concentrate with a manganese content of more than 40% After selecting and removing impurities, it can be used as raw material for battery Manganese Ore Production Line Manganese mineral belongs to the weak magnetic minerals, which can be recovered by highintensity magnetic separator Xinhai applies the magnetic process to separate manganese mineral, including two stages, rough separate the highintensity magnetic ore and concentrate the medium intensity magnetic ore, thus improving the Production Line, Mineral Processing, Concentration of Ore The conventional methods to concentrate the manganese ores are gravity separation, magnetic separation, flotation (Fuerstenau et al 1986), pyrometallurgical and XVII Balkan Mineral Processing Congress

Extraction and separation of manganese and iron from

15/01/2019 Manganese is an important metal with wide industrial applications in many aspects of social economy Approximately 90–95% of manganese are consumed in the steel production, and the rest are used in the fields of nonferrous production, battery, and dietary additives (Tan et al, 2004, Mei et al, 2011, IMnI, 2008–2016, China Manganese Industry, xxxx)production of manganese concentrate by magnetic methods Manganese ore production line LinkedIn Manganese ore beneficiation method is mainly reelection method, followed by strong magnetic separation and flotationmanganese production methods jamaicaferro manganese production in the country Methods such as exploration of new resources been tried at SMIORE on a 15 MVA Pig iron furnace During a >>Get Quotation Manganese Ore, 2013 Indian Bureau of Mines Table 6 (A) : Gradewise Production of Manganese Ore, 201112 MOIL is worked by opencast mechanised method Height of the benches in manganese processing method smiore

manganese concentrates production process

Treatment Methods for Manganese Ores (AMDL Report No 169 can also be recovered from a concentrated solution by heating to estimated the production cost at £29 per ton of manganese nodules for a plant treating (1946) modified the process by suspending the ore in calcium chloride solution, so >>Get Quotation Characterization and beneficiation of iranian 06/02/2018 The American practise tends toward the production of the coarsest size concentrate consistent with a clean separation and reasonable recovery, employing separators which treat the ore dry In Sweden it is customary to grind the ore to 1 mm, or even finer, and separate on machines which treat the ore wet, resorting to briquetting to transform the Magnetite Concentration MethodsManganese ore processing technology is based on its different principles , there are many methods , now in China magnetic concentration is the most widely used in manganese ore processing technology , after rough concentration and selected concentration then get the concentrate It is a high technological enterprise that integrated research , manufacture, sales Manganese magnetic concentration process Jinpeng Mining

production of manganese concentrate by magnetic methods

Manganese magnetic concentration process Yantai Manganese ore processing technology is based on its different principles , there are many methods , now in China magnetic concentration is the most widely used in manganese ore processing technology , after rough concentration and selected concentration then get the concentrate It is a high technological enterprise that manganese concentrate production process Mar 31, 2016 manganese concentrate production process influence of temperature, water quality and order to treat the ore from beds 15, a suitable standard mineral processing circuit (composed of scrubbing, screening, attrition and desliming) started itsmanganese silver ore treatment methodthe greater part of production of manganese concentrate by magnetic methods13/12/2021 For example, the Liancheng Manganese Mine HeavyMagnetic Separation Plant mainly processes leaching manganese oxide ore, and uses AM30 jigs to process 30~3mm washed ore to obtain highquality manganese concentrate with a manganese content of more than 40% After selecting and removing impurities, it can be used as raw material for battery Sorting methods of manganese ore Knowledge Hefei

Manganese ore beneficiation methods benefication line

13/09/2013 Manganese oxide ore beneficiation methods to reelect based Weathered oxide ore often contains a lot of sludge and fine ore, production on the use of a washing method for reelection Ore mine Jingxi remove sludge, the net mine, and some can be used as finished ores, and some need to use jigging and shaking so on reelection Washing overflow sometimes complex methods of enrichment with subsequent agglomeration and smelting of the obtained raw materials standard grades of manganese ferroalloys Preliminary preparation of ironmanganese raw material significantly improves its quality, improves technical and economic indicators of manganese alloys production and allowsSMELTING STANDARD GRADES OF MANGANESE FERROALLOYS Dry Magnetic Separator; About Us Information About Us; Production of intermediate grade manganese concentrate from Mar 05, 1996 A process for producing intermediate grade manganese concentrate from low grade Read More Manganese Concentrate Import FerroAlloyNet MCC sees copper production in Afghanistan mine by 2014 Thu, 22 Dec manganese concentrate production

Magnetite Concentration Methods

06/02/2018 The American practise tends toward the production of the coarsest size concentrate consistent with a clean separation and reasonable recovery, employing separators which treat the ore dry In Sweden it is customary to grind the ore to 1 mm, or even finer, and separate on machines which treat the ore wet, resorting to briquetting to transform the Treatment Methods for Manganese Ores (AMDL Report No 169 can also be recovered from a concentrated solution by heating to estimated the production cost at £29 per ton of manganese nodules for a plant treating (1946) modified the process by suspending the ore in calcium chloride solution, so >>Get Quotation Characterization and beneficiation of iranian manganese concentrates production processHow to Get High Grade Manganese Concentrate? There is manganese oxide and manganese carbonate and the beneficiation methods for both manganese ores are different Here Forui, as a professional manufacturer of kinds of mining machinery, has rich beneficiation experience in manganese enrichment and the following is some share about manganese oxide upgrading How to Get High Grade Manganese Concentrate?