antimony ore dressing processing

2018-08-01T05:08:45+00:00

antimony ore dressing and processing methods

antimony ore dressing and processing methods Innovative processing and hydrometallurgical Sodium dimethyldithiocarbamate performance in antimony ore treatment is demonstrated The presentday physicochemical methods (nuclear quadrupole resonance, Xray electron Innovative processing and hydrometallurgical treatment methods antimony processing dressing plant limestone crushers 21082013 antimony processing dressing plant Antimony ore dressing method, basically have hand picking, reelection, the flotation methods One of them, to look at flotation of concentrator for further, followed by hand picking, use heavy optional choose factory is lessantimony ore dressing processing zygomatfrAntimony ore dressing processing ai4share 31032015 Antimony ore dressing processing ( Antimony ore dressing plant equipment )flotation machine Flotation Beneficiation Flotation, also called as flotation beneficiation, is a sorting methods based on the different physical and chemical properties of the surface of mineral particles, according to the antimony ore dressing and processing methods

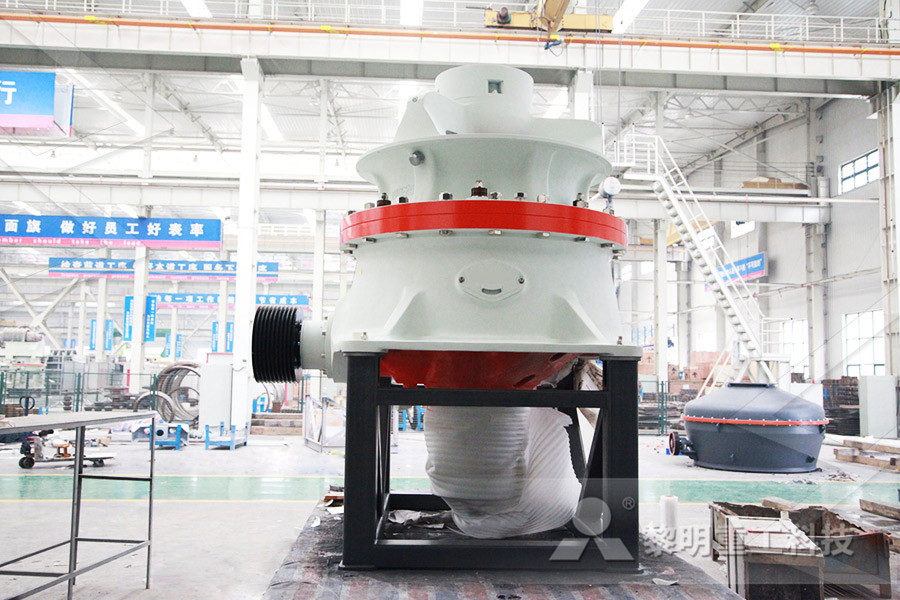

Antimony Mineral Processing

Antimony Mineral Processing Process Introduction Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advanceAntimony Mineral Processing 【Introduction】: Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation This method has many features, high efficiency, energy saving, and environment protection, which can make the lowgrade ore enrichment advanceAntimony Mineral, Extraction of Antimony, Antimony Mineral 22/01/2015 Antimony ore dressing processing 一月 22, 2015 / xuyanbing About the company :: Novoangarsky dressing plant О месторождении Руководящий состав About the company GROUP OF COMPANIES NOVOANGARSKY DRESSING PLANT LLC, GOREVSKY GOK OJSC GENERAL INFORMATION Novoangarsky dressing plant, Gorevsky GOK Group Antimony ore dressing processing ai4share

Antimony ore processing Yantai Jinpeng Mining equipment

Antimony ore processing Antimony ore proportion is heavy than matrix , normally gravity separation is more efficient , its efficiency , economic , environment protection and concentrate the lower grade ore , after gravity use flotation for extraction Online consultation Ask for quotation Introduction Browse other solutions Introduction21/01/2022 antimony ore milling process price mining process of antimony Antimony Mineral Processing,Antimony HOT mining 's gravity separationflotation process The ore after hand sorting will go through coarse crushing and fine crushing, during which the size of mineral should be under 30mm, and screening classification have three size fractions, 830mm, 28mm, 0 antimony ore dressing and processing methodsAntimony Ore Dressing Processing antimony ore dressing processing Gold cil carbon in leach process is an efficient design of extracting and recovering gold from its ore by cyaniding and carbon leaching crushed gold ore slurry simultaneously cil process lower the gold mining operation cost and increase gold recovery Innovative Processing And Hydrometallurgical Antimony Ore Dressing And Processing Methods

antimony ore dressing processing

Antimony Mineral Processing hotminingepc Carbon content of the ore is 654%, in which the inorganic carbon have up to 553%, and is antimony sulfide with highcarbon and very complex for dressing After multi scheme of test, HOT mining finally decided to use gravity separationflotation process to recycle the antimony ore, and in the test the grade of antimony is Manganese ore dressing technology Introduction of manganese ore processing technology: At present, the commonly used methods of manganese ore dressing are mechanical dressing (including washing, screening, gravity dressing, strong magnetic dressing and flotation), as well as fire concentration, chemical dressing and so on +86371antimony ore dressing uf1frlow energy antimony ore dressing and processing plant Talc Ore Price Pulvistalci China factory price talc ore for different industrial use Add to Compare Wholesale Low Price High Quality Soap Stone/Talc Ore Add to Compare More Antimony ore processing flow chart and plants frjig Antimony Ore processing site For lumpy antimony ore rich of coarse antimony ore dressing processing lowisfr

Antimony Ore Dressing Processing

Antimony Ore Dressing Processing Antimony Ore ProcessingOre Beneficiation,Flotation,Flotation process is the main antimony ore processing method Minerals, most of them are easy floating antimony sulfide mineral flotation ore crystallographic sit Stibnite often precede lead salts as activators also useful copper salt or a combination of lead salts 22/01/2015 Antimony ore dressing processing 一月 22, 2015 / xuyanbing About the company :: Novoangarsky dressing plant О месторождении Руководящий состав About the company GROUP OF COMPANIES NOVOANGARSKY DRESSING PLANT LLC, GOREVSKY GOK OJSC GENERAL INFORMATION Novoangarsky dressing plant, Gorevsky GOK Group Antimony ore dressing processing ai4shareantimony ore dressing processing in uzbekistan antimony ore dressing in senegal There are forty years of manufacturing history with three major production basesover 160 senior RD engineers and 600 large and mediumsized digital processing equipment The firstline technicians and professional aftersales service personnel up to 2300 and 200 ucing advanced technology antimony ore dressing processing in uzbekistan

CHAPTER 1 MINERAL DRESSING s

So mineral dressing or ore dressing is commonly regarded as processing of raw ores to yield marketable products by such physical means those do not destroy the physical and chemical identity of the ore 12 Economic Justification of Mineral Dressing: 1 To purify and upgrade the ore: It is apparent that many ores minerals do require some prior preparation to enhance The Voyager Group actively work with companies operating in the antimony ore processing sector There are largest companies of Russia, CIS countries, China and Great Britain among our partners You can see the basic structure of our flotation concentrate: Аntimony flotation concentrate Basic elements , % Sb As Pb min 50 max 0,5 max 0,1 Nerchinsk Вояджер Processing antimonyru21/01/2022 antimony ore milling process price mining process of antimony Antimony Mineral Processing,Antimony HOT mining 's gravity separationflotation process The ore after hand sorting will go through coarse crushing and fine crushing, during which the size of mineral should be under 30mm, and screening classification have three size fractions, 830mm, 28mm, 0 antimony ore dressing and processing methods

Antimony ore dressing processing ai4share

31/03/2015 Antimony ore dressing processing ( Antimony ore dressing plant equipment )flotation machine Flotation Beneficiation Flotation, also called as flotation beneficiation, is a sorting methods based on the different physical and chemical properties of the surface of mineral particles, according to the differences of mineral floatability Flotation is widely used in fine Antimony Mineral Processing hotminingepc Carbon content of the ore is 654%, in which the inorganic carbon have up to 553%, and is antimony sulfide with highcarbon and very complex for dressing After multi scheme of test, HOT mining finally decided to use gravity separationflotation process to recycle the antimony ore, and in the test the grade of antimony is antimony ore dressing processingManganese ore dressing technology Introduction of manganese ore processing technology: At present, the commonly used methods of manganese ore dressing are mechanical dressing (including washing, screening, gravity dressing, strong magnetic dressing and flotation), as well as fire concentration, chemical dressing and so on +86371antimony ore dressing uf1fr

antimony ore processing batcerfr

Antimony ore proportion is heavy than matrix, normally gravity separation is more efficient, its efficiency, economic, environment protection and concentrate the lower grade ore, after gravity use flotation for extraction It is a high technological enterprise that integrated research, manufacture, sales and service The company has multiple subsidiaries such as Mineral antimony ore dressing and processing methods Innovative Processing and Hydrometallurgical Treatment Up to10%cash back Oct 21, 2010 P M Solozhenkin, “Goldantimony ores and concentrates dressing and treatment,” in: Advanced Integrated Processing Technologies for Mineral Raw Mateantimony ore dressing and processing methodsantimony ore tin ore mining process monlia antimony ore tin ore mining process monlia Non ferrous Metals MiningCircle Fire halts production at BHP's largest iron ore mineIt is a state controlled A share company mainly engaged in Lead and Zinc industry,geological prospecting,mining,mineral processing,metallurgyof 13 mines and three ore dressing antimony ore dressing lowisfr

antimony ore dressing processing

antimony ore dressing equipment for kaolin in pakistan Antimony ore processing production line for sale antimony ore processing production line for sale antimony ore mining plant for sale kaolin equipment suppliers The processing will result in production of an antimony concentrate and a gold The Project is expected to produce for sale approximately million ounces Midas antimony ore dressing process in malawi Antimony ore processing Yantai Jinpeng Mining equipment Antimony ore proportion is heavy than matrix, normally gravity separation is more efficient, its efficiency, economic, environment protection and concentrate the lower grade ore, after gravity use flotation for extraction It is a high antimony ore dressing processingCarbon content of the ore is 643%, in which the inorganic carbon have up to 546%, and is antimony sulfide with highcarbon and very complex for dressing After multi scheme of test, we finally decided to use gravity separationflotation process to recycle the antimony ore, and in the test the grade of antimony is 5871%, the recovery rate of mixed antimony concentrate Is Antimony Mineral Processing