iron ore pilot plant beneficiation

2020-07-11T12:07:48+00:00

Steel News

21/12/2021 12/21/2021 Metalloinvest announced last week the launch of a pilot plant at Mikhailovsky GOK intended to model iron ore beneficiation processes and develop new highquality products In a press release, the company said it developed the unique pilot plant with specialists from the TOMS Institute “A beneficiation plant in miniature has been 24/11/2021 Iron ore is an important raw material for steel production enterprises In most cases, iron ore with a grade of less than 50% requires ore beneficiation before smelting and utilization Natural ore (iron ore) is gradually selected for iron through procedures such as crushing, grinding, magnetic separation, flotation, and gravity separationWhat is iron ore beneficiation? Tisco Steel Co, Ltdiron ore beneficiation concentration flow chart beneficiation of iron ore plant flow chart Beneficiation of Iron Ores – IspatGuru Apr 03, 2014 For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the Sheet Design For Iron Ore Benification Plant

BENEFICIATION OF IRON ORE nitrklac

Appropriate beneficiation process has to be advanced to reduce the waste generation in mines and for the sustainable growth of the iron ore industry some Major reason for difficulty in beneficiation of BHJ is revealed from characterization studies which show the intergrowth of haematite and quartz03/04/2014 Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron magnetite) Ores are normally associated with unwanted gangue material Grade of iron ore is usually determined by the total Fe content in the ore Run of mines ores after dry or wet Beneficiation of Iron Ores IspatGuruThe inclusion of medium intensity magnetic drum separation (MIMS) in combination with jigging may be considered for the beneficiation of the 61mm fraction of some friable ore bodies The following diagram demonstrates some typical flowsheet designs for Iron Ore beneficiation of hard rock and friable ores Innovative Plant DesignIron Ore Mineral Technologies

RBSSN

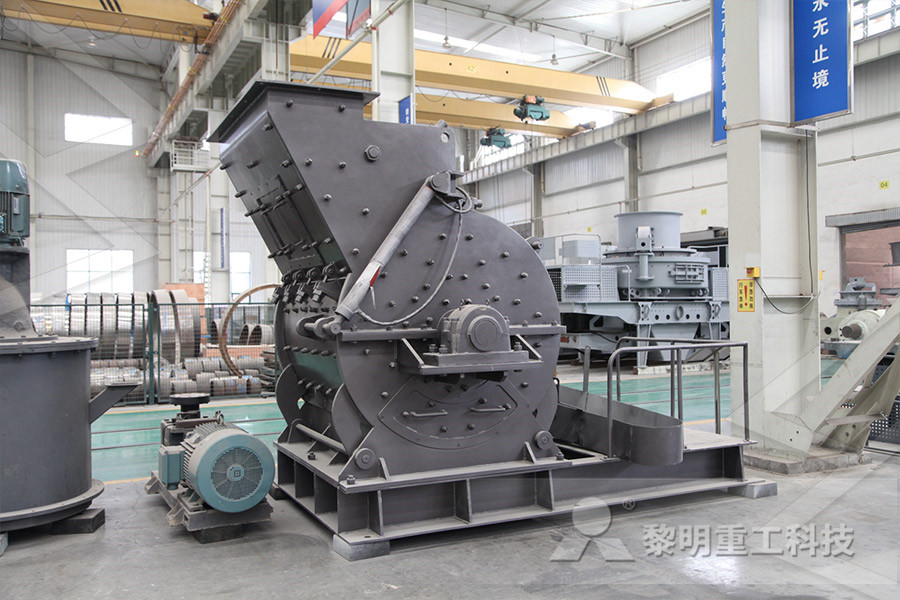

Plants are designed to upgrade the Lowgrade Fine size and coarse size range of materials This upgradation is achieving through the use of various process equipment’s Following Main equipment’s are in Our Beneficiation Plant: 1 Gravity concentration equipment’s 2 Magnetic Separators 3 Classification equipment’s 4 Sizing equipment’s 5Laboratory and pilot testing Beneficiation testing on a small or large scale in close collaboration with worldrenowned laboratories, institutes, and universities Process and plant audits Audits of current production processes at the plant aimed at identifying potential for improvements are carried out by experts in the fields of metallurgy, engineering, operation, and automation Iron Ore Beneficiation Primetals Technologies27/03/2018 A typical flow sheet for iron ore benefaction plant is shown in Fig 1 3/13 Fig 1 A typical flow sheet of iron ore benefaction plant Some of the common methods/ techniques applicable for iron ore processing are described below Order custom essay Beneficiation of Iron Ores with free plagiarism report GET ORIGINAL PAPER Crushing, grinding and Beneficiation of Iron Ores PHDessay

Iron ore beneficiation plant aaelecfr

In iron ore mining, miner usually choose a complete iron ore crushing plant for metallurgy Iron ore beneficiation process Almost all of the iron ore that is mined is used for making steel So we need the extraction of a pure metal from its ore The extract the metal from ores, several physical and chemical methods are used The method used depending upon chemical Jun 28, 2018 beneficiation plants for upgrading iron ore and pelletizing plants for iron ore The quality of iron ore deposits, however, has deteriorated be processed in a sintering plant and must be designed for the steelworks of the owner company More Stable growth in steel pellets quality at Poltava Mining These additional cells gave a step change in the concentration pilot plants in iron ore processing lowisfrsolutions for Iron Ore Beneficiation Testing Process Design Mineral Technologies undertakes professional sample and pilot plant test work for a wide range of minerals including iron ore Our metallurgists are experienced in the complete range of analytical, bench, pilot and industrialscale testing using wet and dry processing techniquesGlobal Capability

BENEFICIATION OF IRON ORE nitrklac

22 Resources/Reserves of iron ore deposit in India 7 23 Processing of Iron ore in India 8 24 Slimes of Iron ore 11 3 BENEFICIATION PLANT STUDY OF NOAMUNDI IRON ORE MINE 14 31 Mineral Processing 15iron ore beneficiation concentration flow chart beneficiation of iron ore plant flow chart Beneficiation of Iron Ores – IspatGuru Apr 03, 2014 For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the Sheet Design For Iron Ore Benification PlantThe following diagram demonstrates some typical flowsheet designs for Iron Ore beneficiation of hard rock and friable ores Innovative Plant Design Having developed an effective and optimised flowsheet, you need a plant that safely Iron Ore Mineral Technologies

Beneficiation of Iron Ores IspatGuru

03/04/2014 Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % Beneficiation is the process where ore is reduced in size and gange separated from the ore Since all iron ore deposits have unique mineralogy, the beneficiation process is specific to each deposit Separation of certain minerals can be efficiently achieved by taking advantage of the physical, electrical and magnetic properties SGS provides a comprehensive range of test SGS MINERALS SERVICES – T3 SGS 960 112009Laboratory and pilot testing Beneficiation testing on a small or large scale in close collaboration with worldrenowned laboratories, institutes, and universities Process and plant audits Audits of current production processes at the plant Iron Ore Beneficiation Primetals Technologies

Global Capability

solutions for Iron Ore Beneficiation Testing Process Design Mineral Technologies undertakes professional sample and pilot plant test work for a wide range of minerals including iron ore Our metallurgists are experienced in the complete range of analytical, bench, pilot and industrialscale testing using wet and dry processing techniquesiron ore pilot plant beneficiation; iron ore pilot plant beneficiation all physical separation techniques can be tested at sgs, both on laboratory scale and scale the commonly used techniques follow: • Get Price Relate Product Get Quick Quote If you have any problems or questions about our products or need our support and assistance, please contact us and you iron ore pilot plant beneficiationResults of pilot plant beneficiation studies undertaken on Indian iron ores as well as limestone are briefly outlined Studies on Indian iron ores have indicated that washing is an absolute necessity to solve the problem of handling sticky and wet ore, and also to yield sized lumpy ore free from adhered fines for blastfurnace charging Heavy media separation and jigging of the Beneficiation, sintering, and processing of raw materials

Sheet Design For Iron Ore Benification Plant

iron ore beneficiation concentration flow chart beneficiation of iron ore plant flow chart Beneficiation of Iron Ores – IspatGuru Apr 03, 2014 For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the and pilot plant scale The commonly used beneficiation techniques follow: • Gravity Separation Spirals are the most practical equipment to use for gravity separation of iron ores because of the high throughputs needed SGS has a variety of spiral test rigs, including the spiral designs typically used in ironore plants Our accessory equipment allows sizing of feeds, multiple Statement of Capabilities for Iron Ore SGSOur Plants are customized type, before material treating to the Plant feasible studies are carried out in wellequipped Pilot Plant Our Pilot Plant We have set up a pilot plant, with the same equipment as our iron ore beneficiation RBSSN

Beneficiation of Iron Ore Fines by Conventional Flotation

studied on a pilot scale at Greater Ferromet Beneficiation Plant of Mis Sociedade De Fomento Industrial Ltd, Goa Reverse flotation process was adopted wherein gangue minerals silica and alumina were floated using cationic amine collector Sodium hydroxide and starch were used to regulate the slurry pH and to depress iron ore, respectively Various iron ore samples drawn Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity Iron Ore Processing,Crushing,Grinding Plant Machine Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice This also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and iron ore Archives Mineral Processing Metallurgy