iron ore mineral processing machine and process

2019-10-21T10:10:36+00:00

Iron Ore Processing,Crushing,Grinding Plant Machine

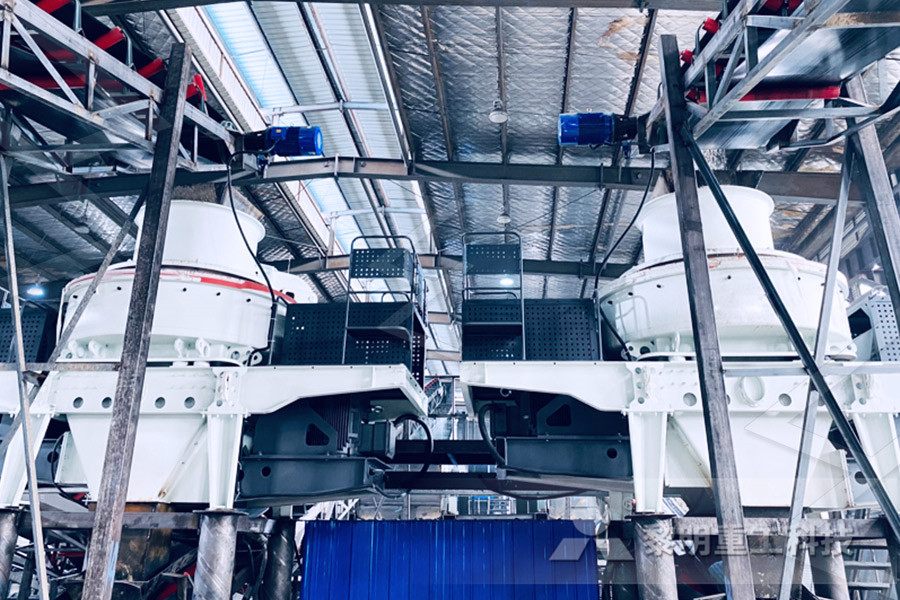

Iron Ore Processing Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be The main iron ore mining equipment includes jaw crushers, ball mills, magnetic separators, spiral classifiers, jig concentrators and related auxiliary equipment such as ore dryers Jaw crusher reduces the hard iron ore into a smaller size, Iron Processing Equipment, Process Flow JXSC 14/03/2018 When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles The Six Main Steps of Iron Ore Processing Multotec

iron ore processing plant, iron ore mining machine

【Process Description】 1Large raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller After first crushing, the material will transferred to cone crusher by belt conveyor for Iron ore is an important raw material for iron and steel production enterprises After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore) It is the mineral aggregates Iron Ore,Production Process of Iron Ore,Iron Ore 14/03/2018 When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles The Six Main Steps of Iron Ore Processing Multotec

Iron or mining processing equipment Schenck Process

The harsh environment and varied bulk material sizes in iron ore mining and processing demand technology that’s both durable and can be adjusted to your unique needs Working in close partnership with the world’s largest iron ore producers over the past 20+ years, we’ve developed a range of solutions that go the extra mile, standing up to extreme site conditions Iron Ore powder processing technological process Phrase one: raw material crushing Iron ore blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder Phrase three: classifyingIron ore grinding mill Grinding plants for Iron OreMining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter (PDF) Life cycle assessment of iron ore mining and

Life cycle assessment of iron ore mining and processing

01/01/2015 Mining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study The environmental impacts considered in the study were embodied energy and greenhouse gas (GHG) emissions 23 Processing of Iron ore in India 8 24 Slimes of Iron ore 11 3 BENEFICIATION PLANT STUDY OF NOAMUNDI IRON ORE MINE 14 31 Mineral Processing 15 32 Primary Beneficiation Plant 15 ~ V ~ 321 Working of Primary Beneficiation Plant 15 33 Secondary Beneficiation Plant 18 331Wet Processing 19 332Dry Processing 23 34 Project BENEFICIATION OF IRON ORE nitrklac20/08/2019 When the content of sulfur and phosphorus in iron ore is high, the pig iron is brittle, and the mineral processing process to reduce the content of sulfur and phosphorus is necessary Iron concentrate used in magnetic Comprehensive Analysis of Mineral Processing

Beneficiation of Iron Ore Mineral Processing

24/05/2016 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast Driven by a global team of process engineers and metallurgical specialists, Multotec designs, builds, manufactures, installs and maintains equipment throughout the entire value chain of mineral processing plants across all Mineral Processing Equipment MultotecThe harsh environment and varied bulk material sizes in iron ore mining and processing demand technology that’s both durable and can be adjusted to your unique needs Working in close partnership with the world’s largest iron ore producers over the past 20+ years, we’ve developed a range of solutions that go the extra mile, standing up to extreme site conditions Iron or mining processing equipment Schenck Process

Iron ore grinding mill Grinding plants for Iron Ore

Iron Ore powder processing technological process Phrase one: raw material crushing Iron ore blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder Phrase three: classifyingCouncil for Mineral Technology The Latest Developments in Iron Ore Processing 5 June Isabel King Iron ore Processing • Overview –Suppliers, sources early days • Crushing Techniques • Processing Options –Coarse processing –Fines processing • Conclusions Introduction: Iron Ore Processing Largest Iron Suppliers • Vale • BHP • Rio Tinto • Kumba Iron ore Overview The Latest Developments in Iron Ore ProcessingMining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter (PDF) Life cycle assessment of iron ore mining and processing

Life cycle assessment of iron ore mining and processing

01/01/2015 Mining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study The environmental impacts considered in the study were embodied energy and greenhouse gas (GHG) emissions 20/08/2019 When the content of sulfur and phosphorus in iron ore is high, the pig iron is brittle, and the mineral processing process to reduce the content of sulfur and phosphorus is necessary Iron concentrate used in magnetic materials is sometimes required to contain less than 04% silicon Such super concentrate must be mineral processed There are too many Comprehensive Analysis of Mineral Processing Methods and 28/04/2016 In iron ore crushing processing is a very important step Tailings recovery process using highfieldstrength Drum Separator roughing, rough concentrate finely ground dizzy fine tailings reelection recovery plant in January 2005 and put into production Currently tailings reelection recovery with the annual processing tailings 10 million t, an annual output of 300,000 Iron ore tailings disposal system process and production

Beneficiation of Iron Ore Mineral Processing Metallurgy

24/05/2016 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring Evolution of binders for iron ore pelletizing Induration technologies Challenges and innovations in iron ore pelletizing 2 Pelletizing process and raw materials The iron ore is mined mostly from open pit deposits through mining operations and the raw product, run of mine, is subjected to mineral processing Thus, the material is exposed to aIron Ore Pelletizing Process: An Overview IntechOpen01/09/2020 While in mineral processing and process mineralogy, texture has a quantitative description with textural parameters such as mineral type and grain size , , Fig 6 illustrates the effective factors of ore texture in the breakage mechanismBreakage process of mineral processing comminution